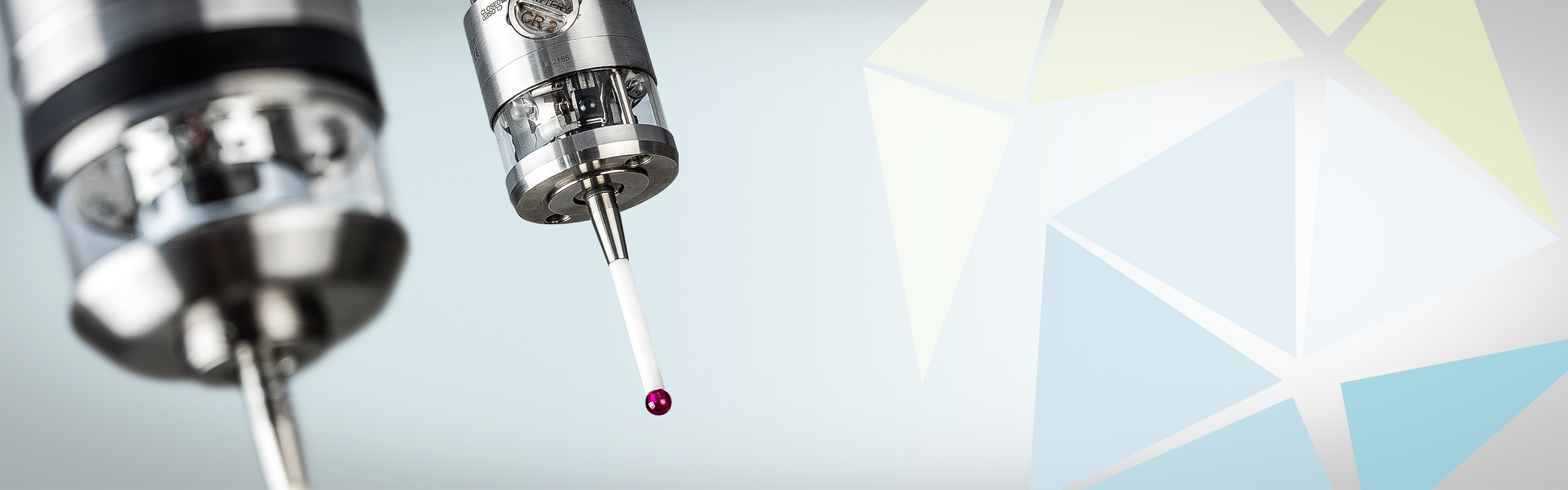

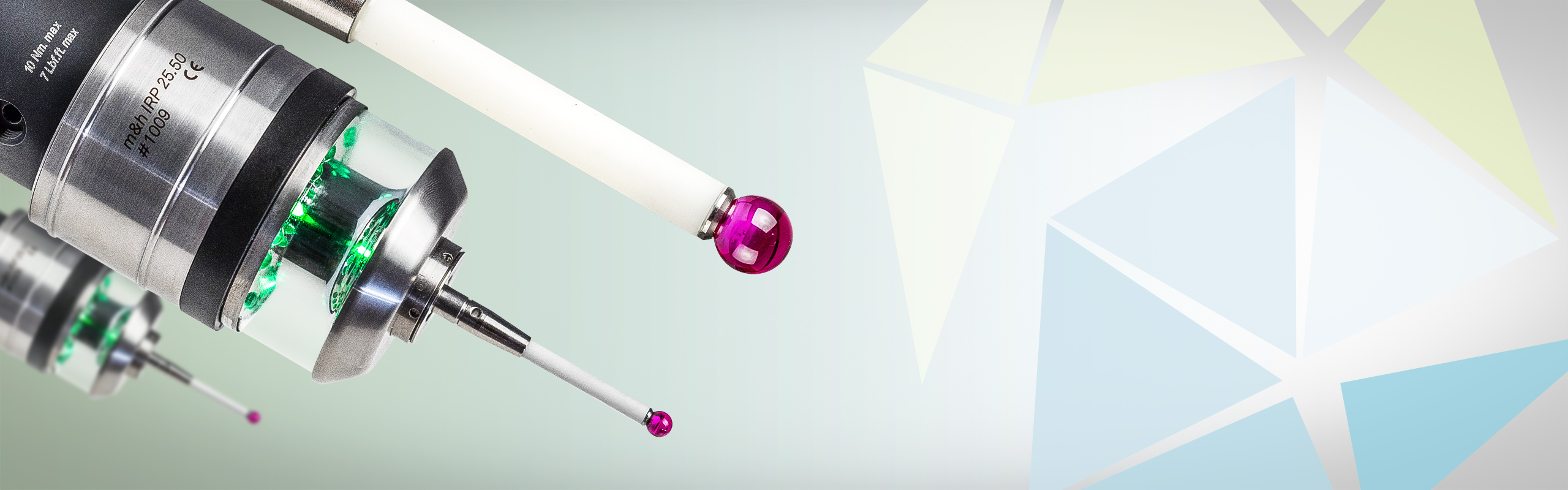

Hexagon Toolsetters

Voor een constante productiekwaliteit is het gebruik van betrouwbare, nauwkeurige gereedschappen nodig. Een essentiële vereiste is nauwkeurige gereedschapsgegevens. Hexagon gereedschaps tasters voor gereedschapsmeting detecteren gereedschapslengte en gereedschapsradius rechtstreeks op de machine. De gegevens worden automatisch overgebracht naar de gereedschapstabel van de besturing. Periodieke gereedschapscontroles op gebroken gereedschappen of slijtage zorgen voor extra productieveiligheid. De gereedschapstaster van Hexagon doet deze taak, bespaart tijd en verhoogt de betrouwbaarheid.

Bezoek de cataloguspagina of neem contact met ons op voor meer informatie.